In an ever-evolving world where efficiency and quality are paramount, the quest for effective sealing solutions has led to remarkable advancements. Among these innovations, the custom Seal King strip emerges as a formidable contender, redefining how businesses approach sealing needs across various industries. This article explores the significance of custom Seal King strips in enhancing operational efficiency, their key features, and their applications.

Automatic lifting sealing strips are specialized sealing solutions that function seamlessly in automated environments. They are typically used in machinery that requires high-speed and accurate sealing processes. These strips are designed to provide a tight seal, preventing contamination, leakage, and loss of freshness. Common applications include food packaging, pharmaceuticals, and other consumer goods that require durable and reliable sealing methods.

In today's fast-paced industrial landscape, the role of seals cannot be understated. Among the various types available, sponge rubber seals stand out due to their versatility, durability, and effectiveness in various applications. Particularly, the segment of wholesale sponge rubber seals has gained significant traction, benefiting businesses across diverse sectors. This article explores the merits, applications, and key considerations surrounding wholesale sponge rubber seals, illustrating why they are an essential component in many industries.

In summary, selecting the right rubber strip window seal supplier is a critical step in ensuring the efficiency and longevity of your windows. By focusing on quality, variety, customization, and support, you can find a supplier that meets your needs and contributes to a comfortable, energy-efficient environment. Investing time in this decision pays off in comfort, cost savings, and peace of mind.

Luminous channel letters are three-dimensional signs that are often used in storefronts, event venues, and outdoor advertising. These letters are generally made from materials such as metal, acrylic, or plastic, with LED lighting integrated into or behind them to illuminate the design. The glow emitted by these letters not only improves visibility during nighttime but also creates an inviting atmosphere that can significantly enhance a brand's appeal.

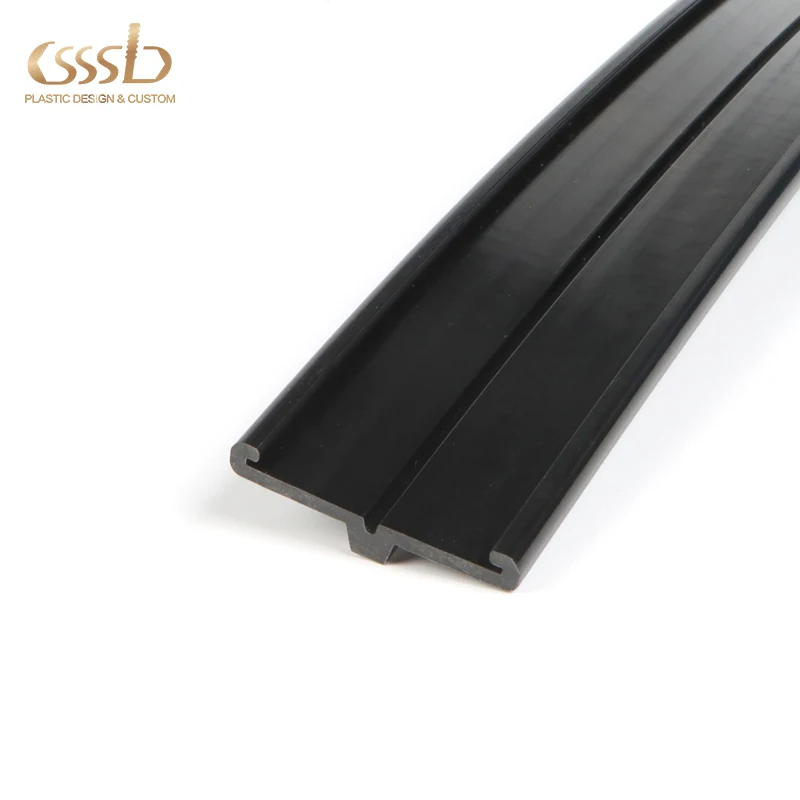

The process of manufacturing window bottom seal strips involves several key steps, each crucial for ensuring the final product's quality and effectiveness. First, raw materials must be selected based on specific requirements, including flexibility, durability, and resistance to weathering. Once the materials are sourced, factories typically engage in extrusion, a method that shapes the material into long strips.

OEM silicone sealing strips offer an array of benefits, including durability, flexibility, and customization, making them an ideal choice for various applications. Their ability to withstand extreme conditions while maintaining a tight seal ensures that manufacturers can produce more reliable and long-lasting products. As industry demands grow, the relevance of OEM silicone sealing strips will undoubtedly continue to rise, solidifying their place as a cornerstone in modern manufacturing.

In summary, high-quality car window strip seals are vital for the protection, comfort, and functionality of your vehicle. They play a significant role in weather resistance, noise reduction, energy efficiency, safety, and aesthetics. By investing in superior seals and considering the factors mentioned, you can enhance your vehicle's performance and prolong its lifespan. Don’t underestimate the power of a good seal—your car will thank you for it!